Consistency

Experience reproducible quality and improved yield rates with our automated and standardized processes, ensuring stable and reliable mass production for your business.

Customized Mass Production

Enjoy fast delivery and flexible high-mix low-volume production models.

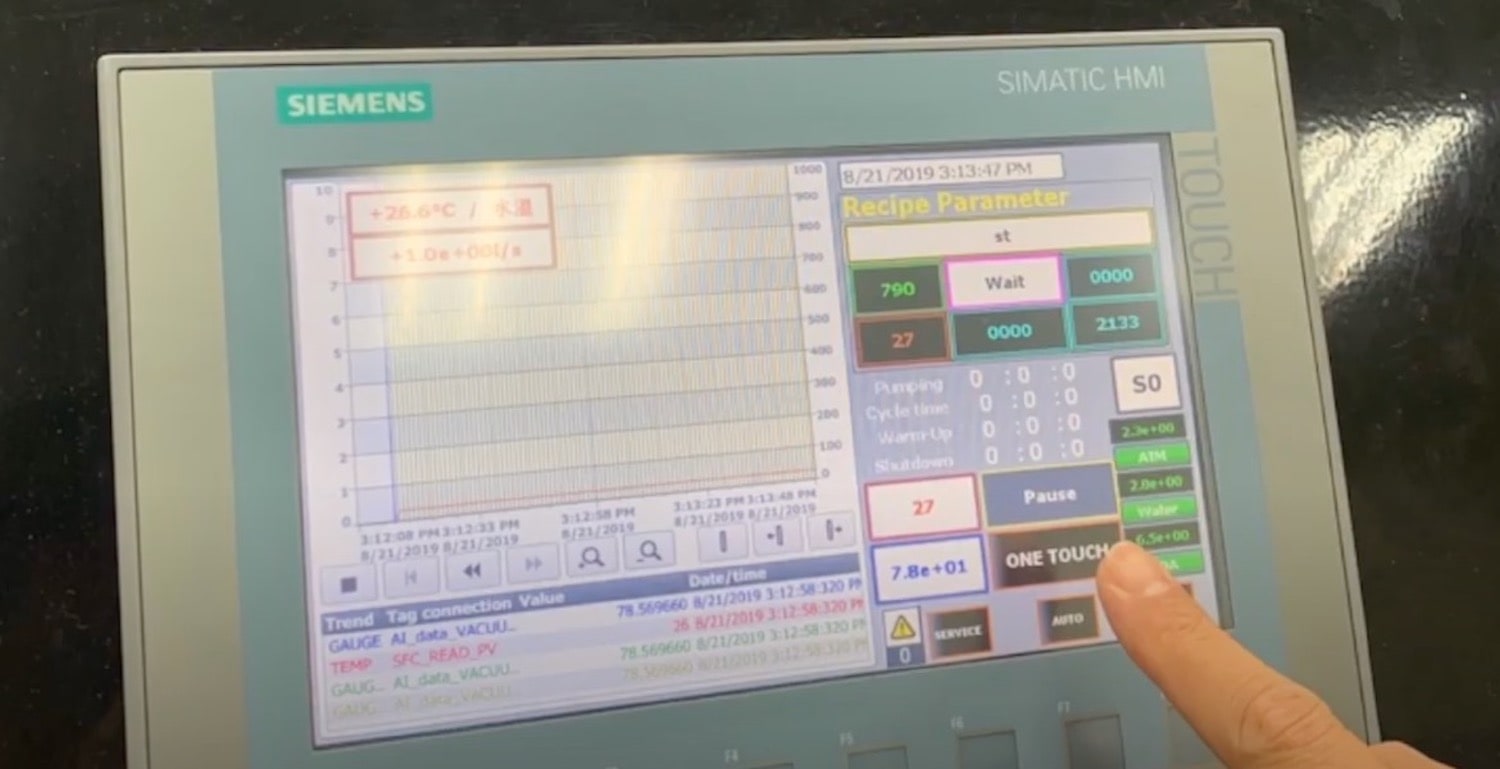

Efficient Production

With One touch, continue seamless production without worrying about experience inheritance crisis and foster innovation.

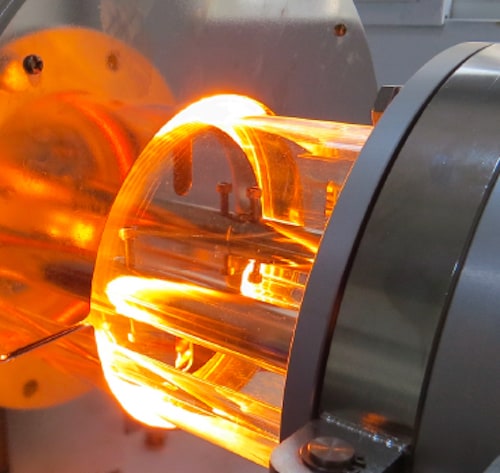

Clean & Green

Enhance workplace safety and reduce environmental footprint.

Easy to Use

No skilled technician required.

Time Saving

Require no cleanup post-brazing and ready to be ground.