Vacuum PCD Brazing Machine for Diamond Tools

2024.03.11

What is PCD Brazing?

|

Vacuum brazing:

|

Let's go through some different types of materials used in vacuum brazing, where PCD, Chemical Vapor Deposition (CVD), and Mono Crystal Diamond (MCD) could be well seamless with your cutting tools to enhance the resilience and efficiency.

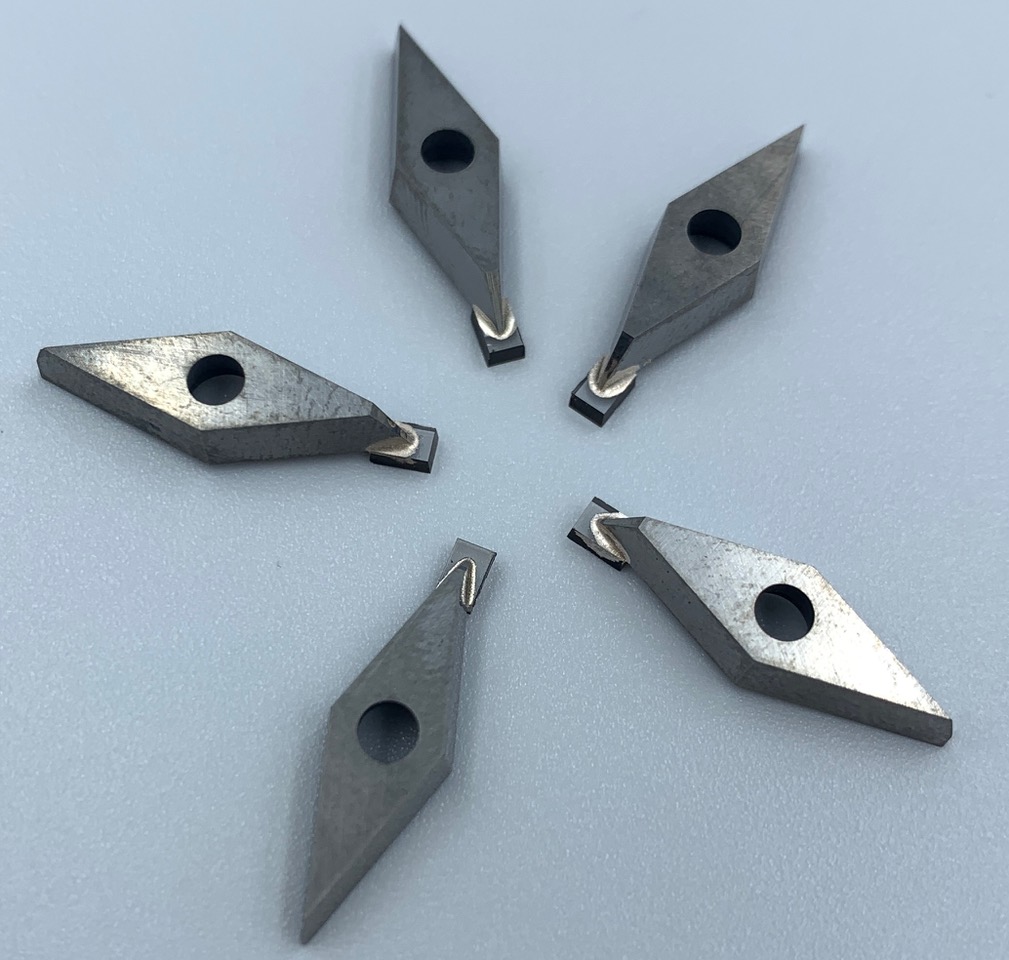

Vacuum Brazing of PCD

|

Let the vacuum brazing PCD technology bolster your tool’s performance through enhanced bonding, ensuring impeccable toughness and reducing the vulnerability to potential breakages.

|

What is PCD?

- Extreme hardness: PCD is almost as hard as natural diamond, making it ideal for machining hard materials like ceramics, composites, and certain metals.

- Excellent wear resistance: PCD retains its sharpness for extended periods, reducing tool wear and downtime.

- High thermal conductivity: PCD efficiently dissipates heat generated during cutting, reducing thermal damage and improving tool life.

- Precision: PCD tools are used in a variety of precision applications with the tightest tolerances.

Exploring Vacuum Brazing with CVD

|

With our innovative techniques, find the perfect blend of coalescence between diamonds, optimizing for superior wear resistance and longevity in your operations.

|

What is CVD?

Chemical Vapor Deposition (CVD) is a microwave plasma process to create free-standing polycrystalline and single crystal CVD diamond.Vacuum brazing: Exclusive for Mono Crystal Diamonds

|

Take your MCDs to the next level with vacuum brazing, the only way to effectively braze single crystal diamonds without damaging their properties and qualities.. This oxygen-free process eliminates weak points, resulting in superior toughness and reduced breakage.

|

What is MCD?

Also known as Mono Crystal Diamond or interchangeable with Single Crystal Diamond (SC), MCD is a synthetic diamond created in a lab with a unique single-crystal structure. This means the entire diamond is formed from a single, uniform lattice of atomsThese diamonds are extremely hard and wear-resistant but can be brittle and susceptible to breakage. They are often used in high-precision cutting applications such as scalpels and optical windows and lenses

Due to this single-crystal structure, MCD boasts exceptional properties:

- Unmatched Hardness and Wear Resistance: MCD boasts the highest hardness of any natural material, making it ideal for applications demanding extreme cutting precision and durability, like scalpels and optical windows.

- Superior surface finishing: MCD achieve the highest surface finish in cutting due to their unique properties.

- Superior Thermal Conductivity: MCD efficiently dissipates heat, preventing tool wear and deformation during high-speed machining, resulting in cleaner cuts and longer tool life.

- Chemically Inert: MCD is virtually resistant to chemical reactions with most materials, making it suitable for cleanroom environments and applications requiring high purity.

- Optical Properties: Due to its exceptional transparency, MCD finds application in specific optical components like lenses and windows for infrared and ultraviolet wavelengths.

Why Choose Pin Power for PCD Brazing?

- Unmatched Precision: We meticulously braze PCD to steel, ensuring impeccable structural integrity and optimal performance.

- Superior Wear Resistance: Our vacuum brazing technology enhances the bonding between diamonds, significantly extending tool lifespan.

- Increased Efficiency: Our advanced PCD brazing machines offer consistent, reliable solutions tailored to modern manufacturing needs.

- Enhanced Productivity: By maximizing tool longevity and performance, we empower your operations to achieve higher productivity levels.

Solutions for Your Needs

|

Our extensive range of PCD brazing solutions caters to diverse needs and applications. |

- Custom PCD Brazing: Tailored solutions to meet your specific requirements and specifications.

- High-Volume PCD Brazing: Efficient large-scale brazing services to support your production demands.

- On-Site PCD Brazing: We bring our expertise directly to your facility for seamless integration into your workflow.

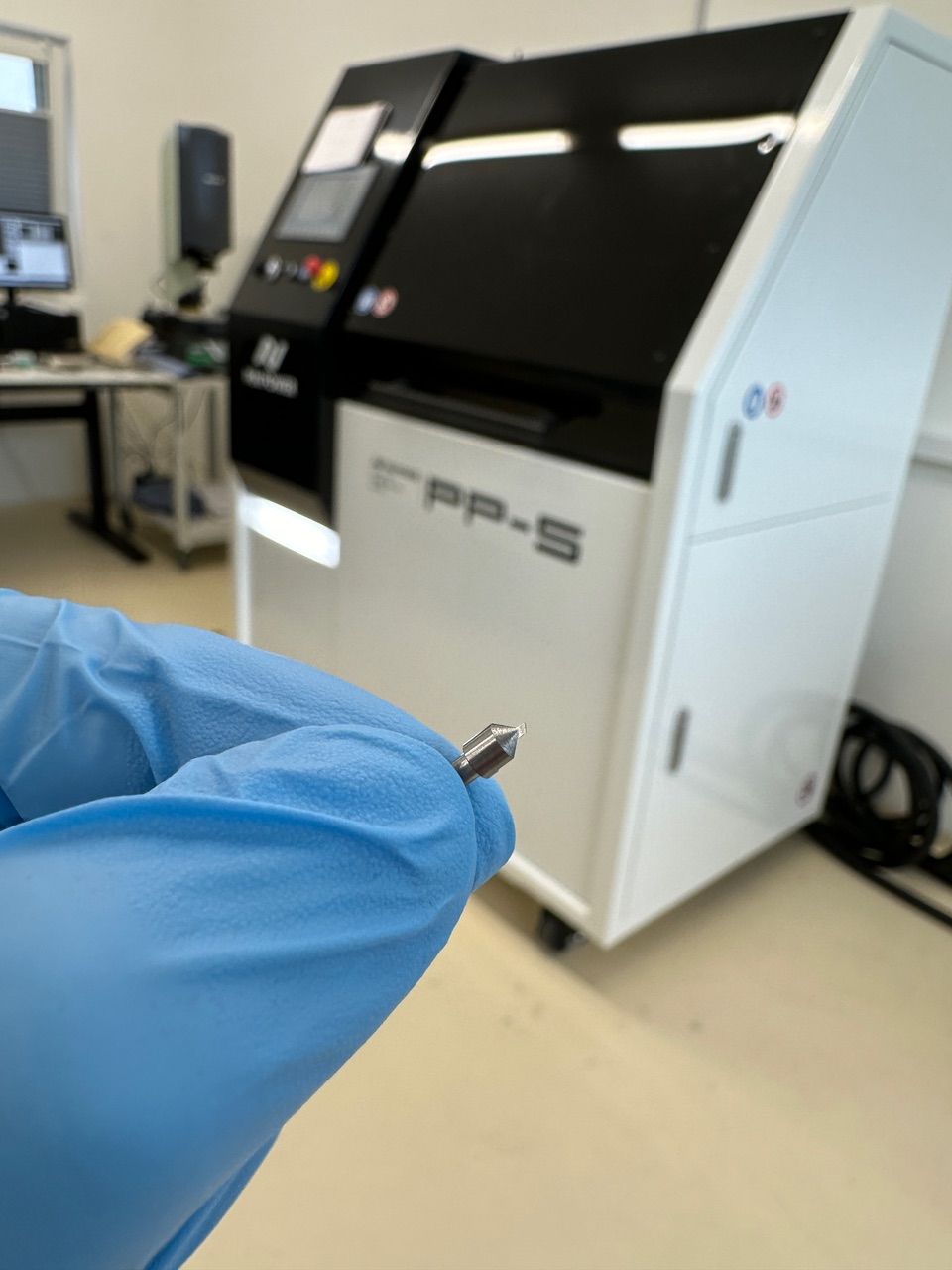

Explore Our PCD Brazing Services Today!

Ready to supercharge your production by integrating our advanced vacuum brazing machine? Propel your manufacturing capabilities to new heights with our unmatched PCD brazing and vacuum brazing solutions.

With our high speed vacuum brazing machine, we are proud to provide you with these benefits and advantages:

- Consistent Quality:

- The brazing process ensures steady and reproducible quality.

- Easy for All Users:

- Any engineer can operate the machinery, reducing the need for experts and cutting labor costs.

- Great Work Environment:

- The machinery contributes to a workspace that is safe, comfortable, neat, and well-organized.

- Diamond Brazing Flexibility:

- Develop innovative tools impossible with other methods, thanks to the ability to braze diverse diamond types.

- Ready for New Opportunities:

- Open doors to unique customer solutions and stay ahead of the competition. The efficiency and productivity brought by brazing are ideal for breaking into new markets and creating new products.

- Reliable and User-Friendly Machinery:

- The PCD brazing machines are trustworthy and easy to maintain.

- Safer Tools:

- It greatly lowers the chance of the tooltips breaking off, a big plus for users.

- No Extra Cleaning:

- No Flux used - therefore no cleaning required after brazing, saves time and gives great appearance.

Contact us today to discuss how our advanced PCD brazing solutions can benefit your business!