How Brazing Diamonds Works & Vacuum Brazing Solutions

2024.03.09

1. What is Brazing?

Let’s break down the term and start with the basics.

At its core, brazing involves the joining of materials using a filler metal with a melting point above 840°F (450°C) but below the melting point of the base metals. In simple terms, brazing is like using a special glue made of metal to stick things together.

In this article, we will explore brazing, focusing on applications involving diamonds due to their significance in various industries.

The following section gets into the specifics of diamond brazing, highlighting its pivotal role in sectors such as automotive and aerospace for processing extremely hard materials and advanced composites, thereby underscoring its utility in modern manufacturing and engineering practices.

1.1 What’s the Difference Between Brazing, Soldering, and Welding?

Brazing, as mentioned earlier, involves joining metals using a filler metal at a certain temperature.

On the other hand, soldering is similar but uses filler metals with a melting point below 840°F. Lastly, welding melts the base metals themselves to create a joint, often adding a filler material for strength. Each method has its unique applications and strengths, depending on the materials and the desired strength of the joint.

| Brazing | Soldering | Welding | |

Use Examples |

(A brazed bicycle frame joint, showcasing its structural strength.source: www.halletthandbuiltcycles.com) |

(A jeweler soldering a small piece of jewelry, requiring precise and focused heat. source: blog.rings-things.com) |

(A welded ship hull, displaying its immense strength and ability to withstand harsh environments. source: www.thefabricator.com) |

| Temperature | Above 840°F |

Below 840°F |

Melts base metals |

Material Strength |

Strong | Less strong than brazing/welding | Strongest |

| Applications | Joining different metals |

Electrical connections, delicate work |

Structural joints in construction, manufacturing |

2. How Does Diamond Brazing Work?

Now we have the definition of brazing, let’s explain how diamond materials are used in this process to make advanced tools.

Diamond brazing is a specialized process within the broader field of brazing, focusing on the attachment of diamond tips to a metal substrate.

The Brazing Process

To understand how diamond materials play a role in this advanced joining technique, let's walk through the steps of the diamond brazing process:

-

Preparation of Surfaces: The metal substrate and diamond tips must be thoroughly cleaned to remove any contaminants that could impair the bond.

-

Application of Brazing Alloy: A suitable brazing alloy, chosen based on its melting point and compatibility with both the diamond and the substrate, is applied. This can be in the form of a paste, powder, or pre-formed shim.

-

Assembly for Brazing: The diamond tips are arranged on the substrate in the desired pattern, and the assembly is positioned for heating. This step often involves temporary fixturing to maintain alignment during the brazing process.

-

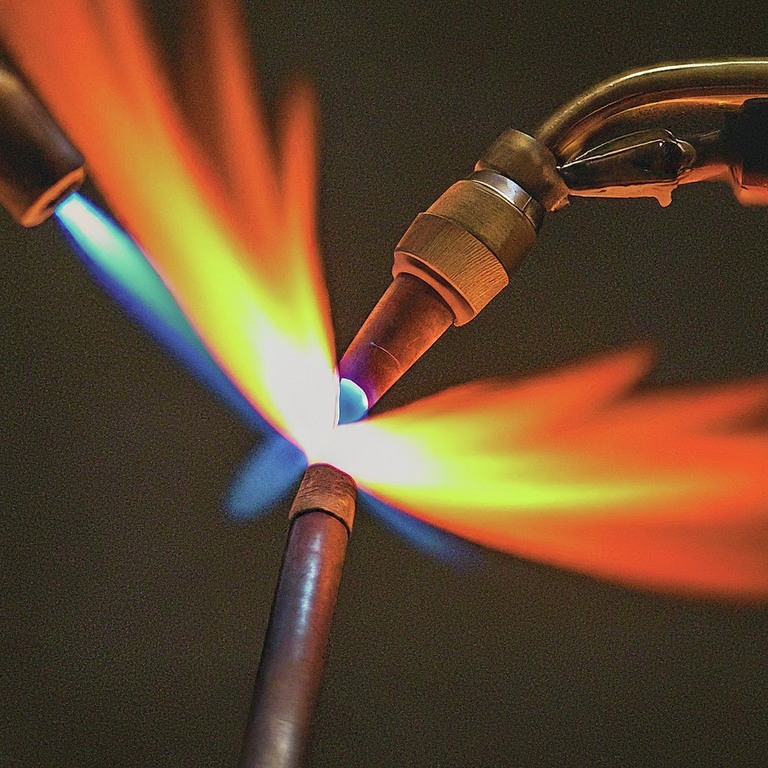

Heating: The assembly is heated to a temperature that melts the brazing alloy but is below the melting points of both the diamond and the substrate. This can be done in a furnace, with a torch, or in an induction heating system, often under a protective atmosphere or vacuum to prevent oxidation.

-

Flow and Wetting: The molten brazing alloy flows by capillary action between the diamond and the substrate, and upon cooling, forms a strong metallic bond that holds the diamond tips firmly in place.

-

Cooling and Cleaning: After the brazing alloy solidifies, the assembly cools down to room temperature. Any residual flux or fixturing materials are then removed, and the brazed tool is inspected for quality.

*It's important not to confuse this process with the use of gem-quality diamonds. The diamonds used in brazing are engineered for industrial applications, not for jewelry. They're chosen for their physical properties, like hardness and thermal conductivity, to enhance the performance of cutting, grinding, and drilling tools.

The success of brazing diamonds to various substrates hinges on understanding and navigating the complexities of material compatibility, thermal expansion, and the selection of appropriate brazing alloys.

Explore robust brazing solutions with Pin Power as we stand out with flux-free production.

2.1 Brazing Diamonds to Steel

Diamonds expand minimally with temperature, while steel undergoes significant expansion. This disparity creates internal stresses and cracking at the interface during heating and cooling cycles, jeopardizing the bond's integrity. A study by Liang Zhang has highlighted this issue, showcasing how the porous nickel interlayer they used offered partial stress mitigation but didn't eliminate it entirely.

Despite these challenges, through the use of advanced brazing alloys and innovative techniques, these compatibility challenges can be effectively managed. The process ensures a strong, enduring bond between diamonds and steel, vital for the performance of cutting and drilling tools in demanding applications.

For example, the high speed vacuum machine ensures a strong, enduring bond between diamonds and steel, crucial for the performance of tools in demanding applications.

3. Brazed Diamond Tools

Brazed diamond tools are renowned for their durability and performance, attributed to the secure attachment of diamond tips to tool substrates. These tools represent a significant advancement in cutting, grinding, and drilling technologies, capable of handling the hardest materials with ease.

The tools can later be used in scenarios as such:

Cutting:

- Saw blades: Used for cutting stone, concrete, asphalt, ceramics, and other hard materials.

- Segmental blades: Employed in large saws for construction and demolition tasks.

- Wire saws: Effective for slicing materials precisely, like silicon wafers and gemstones.

Grinding:

- Cup wheels: Used for grinding concrete, stone, and other surfaces.

- Polishing wheels: Ideal for achieving high-quality finishes on various materials.

- Sinking wheels: Used for creating intricate shapes and profiles.

Drilling:

- Core drills: Extract cylindrical samples from concrete, asphalt, and other materials.

- Bush hammer drills: Create textured surfaces on concrete and stone.

- Glass drills: Used for precision drilling in glass and other brittle materials.

In short, the use of brazed diamond tools significantly enhances operational efficiency by improving productivity, reducing downtime, and minimizing tool replacement costs.

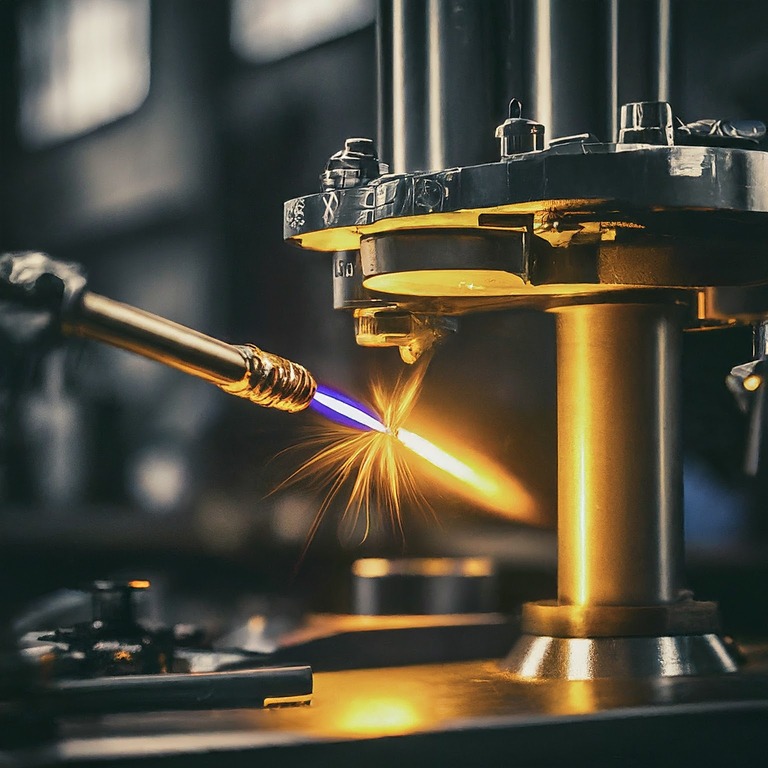

3.1 Vacuum brazing diamond tools

Vacuum brazing offers considerable advantages for brazing superhard materials, including tungsten carbide, ceramics, and diamonds. This technique is distinguished by its ability to maintain the integrity and strength of workpieces, ensuring extremely clean joints without the need for flux.

The controlled heating and cooling cycles in vacuum brazing minimize residual stress, which in turn enhances the thermal and mechanical properties of the material.

Our high speed vacuum brazing machine represents a significant leap in this technology. This automatic model is designed for fast, efficient brazing, capable of handling a wide range of superhard materials.

It greatly shortens the brazing time to about 30 minutes and provides numerous benefits, including improved joint strength, reduced distortion, and a cleaner, safer working environment. With this machine, even those without prior brazing experience can achieve professional-grade results, thanks to its user-friendly, one-touch operation system.

In short, utilizing our high speed vacuum brazing machine comes with numerous advantages:

- Shortened construction period and an improved working environment due to its efficiency and cleanliness.

- Enhanced strength of brazed joints, with bonds being 20-30% stronger than those achieved with silver solder, effectively reducing the risk of tip loss during tool use.

- Controlled heat distribution and precise control minimize variability in joint characteristics, guaranteeing consistent, high-quality tools in every batch.

- Reduced distortion of the materials involved, ensuring higher quality finishes.

- The user-friendly operation doesn't necessitate prior brazing experience, thanks to its one-touch functionality.

- Versatility in handling a wide array of superhard materials, from natural diamonds to various artificial diamonds, makes it ideal for producing a broad spectrum of tool types.

Our machine not only saves significant time by eliminating the need for post-brazing cleanup but also ensures that vacuum-brazed tools have a superior cosmetic appearance, with smooth, even braze lines, and devoid of any voids or pits. Each cycle only requires 1-2 hours, showcasing the machine's efficiency and its role in promoting a clean and safe working environment.

4. How Our Vacuum Brazing Machine Comes into Play

Our high speed vacuum brazing machine offers significant advantages including a faster construction timeline, better work environment, increased joint strength, minimized distortion of materials, and even helps reduce carbon footprint. It's designed to be easy to use, even for those without prior brazing experience, thanks to its one-touch operation feature.

This machine is ideal for working with various types of diamonds and superhard materials such as natural diamond, Mono Crystal Diamond (MCD), Polycrystalline Diamond (PCD), Polycrystalline Cubic Boron Nitride (PCBN), Chemical Vapor Deposition (CVD) diamonds, and single crystal diamond.

- Consistent Quality:

- The brazing process ensures steady and reproducible quality.

- Easy for All Engineers:

- Any engineer can operate the machinery, reducing the need for experts and cutting labor costs.

- A Great Work Environment:

- The machinery contributes to a workspace that is safe, comfortable, neat, and well-organized.

- Diamond Brazing Flexibility:

- Develop innovative tools impossible with other methods, thanks to the ability to braze diverse diamond types.

- Ready for New Opportunities:

- Open doors to unique customer solutions and stay ahead of the competition. The efficiency and productivity brought by brazing is ideal for breaking into new markets and creating new products.

- Reliable and User-Friendly Machinery:

- The machines are trustworthy and easy to maintain.

- Safer Tools, No Extra Cleaning:

- It greatly lowers the chance of the tool tips breaking off, a big plus for users. Also, tools don't need cleaning after brazing, saving time and improving appearance compared to traditional methods.

Our commitment to quality and excellence ensures that each tool and component meets the highest standards of performance and durability.

Whether you're dealing with the challenges of brazing diamonds to steel or seeking the unparalleled performance of brazed diamond tools, we’re ready to deliver robust solutions that drive efficiency and success.

Contact us now to explore a world where superior technology and expertise catalyze to enhance your production capabilities and quality.