How Does an Automatic Vacuum Brazing Help the Brazing Process?

2022.01.05

For many manufacturers and industries, vacuum brazing is a cost effective and high quality solution that continues to gain popularity because of its effectiveness, control, cleanliness of parts, and overall value. Furthermore, because the brazing process happens inside a vacuum chamber where temperature and conditions are closely controlled, the final product is very clean, has high integrity and is very strong. This can benefit their use in manufacturing parts in the automotive, aerospace, and even medical industries.

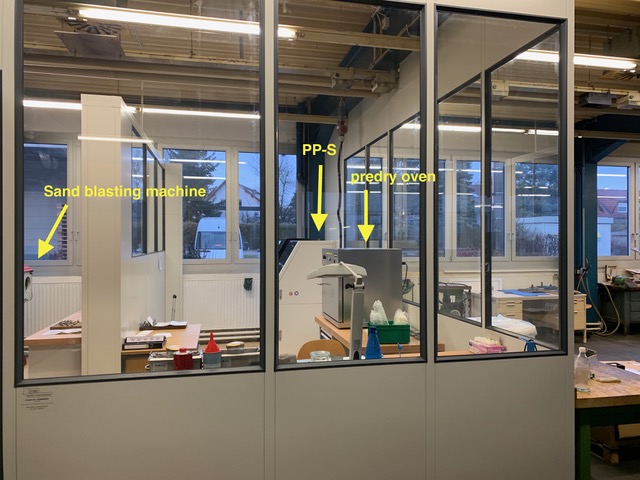

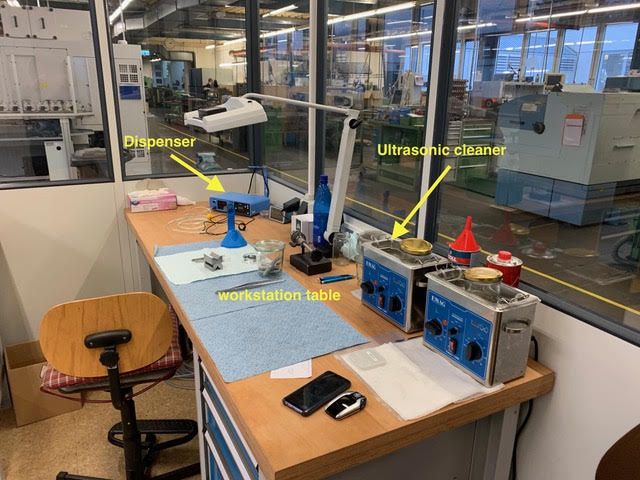

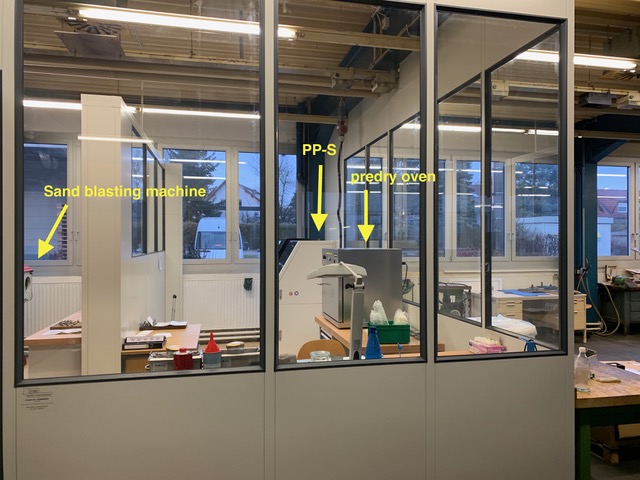

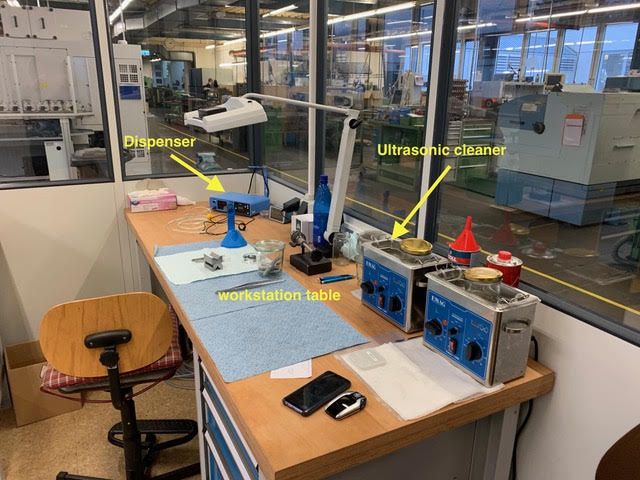

Thanks to fully automatic design of Pin Power PP-S, it saves storage space and makes work smarter and more orderly.

Thanks to fully automatic design of Pin Power PP-S, it saves storage space and makes work smarter and more orderly.